Over the past year, I’ve been able to work on the CalPoly FSAE combustion and electric vehicles for 2022. My main role on the team was on battery systems and drivetrain, two subsystems that tie heavily into each other.

One area that was new to me was creating individual battery packs. Each pack has a 16s9p configuration that allows us to get a maximum voltage of 336V, which means I finally get to deal with high-voltage systems. Each cell has nickel strip fusing so that in the case of a short or over-current situation, the cell with break the fuse and detach from the main part of the pack. This is one of the many ways we attempt to mitigate against a thermal runaway event. We also have a custom BMS that keeps all the cells balanced using passive balancing and goes through multiple checks, such as temperature, overvoltage, under voltage, and more to decide if the pack should stay enabled or become disconnected.

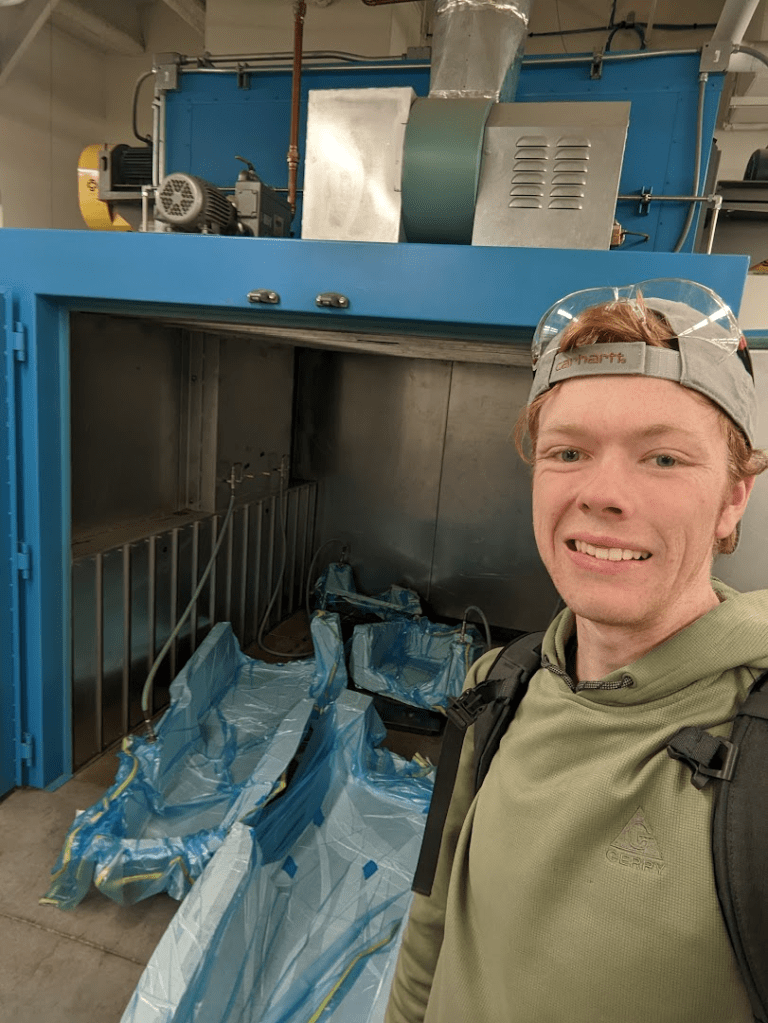

Since everything I made went on a racecar, specific stiffness of parts mattered to get weight down. This is the main reason compelling us to use composites where metal would be cheaper and easier. However, I was able to learn how to do many composite layups, such as infusion (as pictured above), wetlayups, and dry layups using prepreg carbon fiber.

I also took part in the chassis layup as we do a full carbon fiber monocoque for our frame. The main reason driving the decision for a carbon fiber monocoque is to get higher torsional stiffness than you would otherwise be able to get with a steel frame chassis. But we have a 4-part mold that gets bolted together to layup the entire chassis.

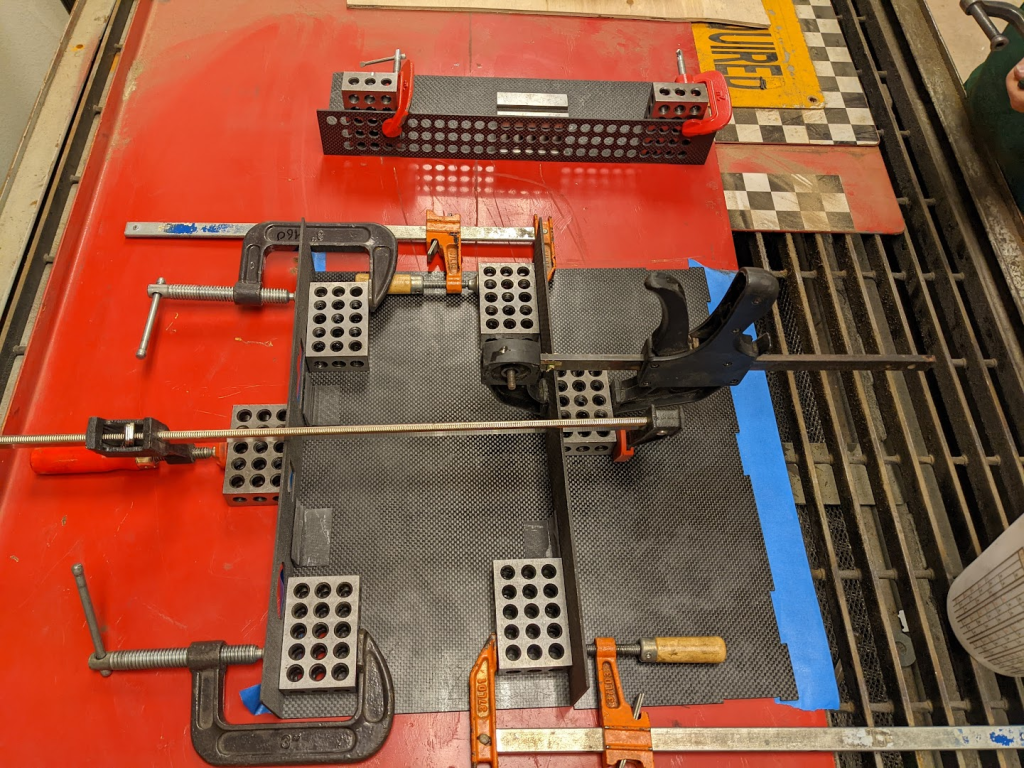

Pictured above is the fixturing we used to bond the panels together on the accumulator (battery pack). The entire accumulator frame weighed in at 11.4lbs, while an equivalent out of aluminum would weigh 15.7, and out of steel 17.7. With the packs and HV assembled, the accumulator weighed in at 101lbs, with next year’s target at <95lbs.

I also worked on the HVD (High-Voltage Disconnect) and the cooling loops for the electric car. The liquid coolant loop cooled the inverter and the motor during use. Without the coolant loop, we experienced over-heating events on both systems, but with loop we were able to alleviate those issues.